CURRENT LEAD TIMES

While we aim to keep products in stock and ready for dispatch, if we are experiencing delays due to local manufacturing constraints - this page is the place to keep informed without contacting us. It shows the current stage of production for the next batch of each product. Once a batch is completed and parts are in stock, if you have an order, you will receive a notification that your items are with QA heading into dispatch. Feel free to call 0450 290 600 or email sales@mirack.com.au for more information on current lead times.

Please note - Custom Carriers (extended models, low clearance models) are not usually held in stock and will require a 'made-to-order' approach, therefore not reflecting the stages shown below. Contact us directly for a better indication on lead times for custom orders.

GEN3 Tilting Spare Wheel Carrier: 100% — In stock

Parts ReceivedAll laser cut parts received and in stock.

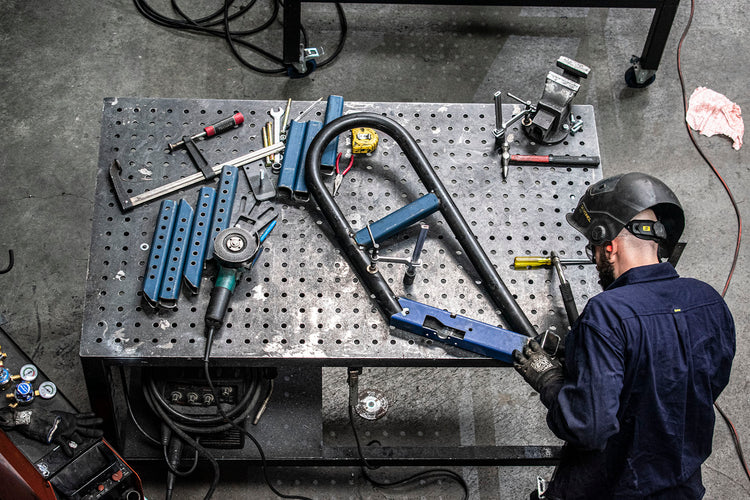

Welding & FabricationAll products MIG welded in-house.

PowdercoatingAll products receive a satin black finish.

QAQuality assurance is done on every product made.

Ready For DispatchCustomers to receive QA notification email.

GEN4 Swinging Hitch Carriers: 100% — In stock

Parts ReceivedAll laser cut parts received and in stock.ETA: Usually takes 2 weeks. Some items from Europe may take longer.

Welding & FabricationAll products MIG welded in-house.ETA: Depending on batch size, 2-3 weeks.

PowdercoatingAll products receive a satin black finish.ETA: 1-2 weeks.

QAQuality assurance is done on every product made.

Ready For DispatchCustomers to receive QA notification email.

Dual Swinging Hitch Carriers: 40%

CuttingAll parts received and in stock.

WeldingAll products MIG welded in-house.

PowdercoatAll products receive a satin black finish.

QAQuality assurance is done on every product made.

Ready For DispatchCustomers to receive QA notification email.

Mirack Folding Tables: 100% — In stock

CuttingAll parts received and in stock.

PowdercoatAll products receive a satin black finish.

QAQuality assurance is done on every product made.

Ready For DispatchCustomers to receive QA notification email.

Jerry Can Brackets: 100% — In stock

CuttingAll parts received and in stock.

PowdercoatAll products receive a satin black finish.

QAQuality assurance is done on every product made.

Ready For DispatchCustomers to receive QA notification email.

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device